Under Armour became famous because of performance fabrics—HeatGear®, ColdGear®, ISO-Chill®, and compression tech that athletes could feel in every workout.

Even in 2025, while many brands shift toward lifestyle wear, UA continues to pour resources into fabric engineering and material science.

As someone who works with performance-focused OEM factories, I’ve seen why technical fabrics remain the backbone of UA’s competitive edge—and why new brands can learn from this long-term strategy.

This article breaks down UA’s innovation approach in a clear, simple, and highly practical way.

Table of Contents

- Quick Answer

- 1. Why Under Armour Still Prioritizes Fabric Innovation

- 2. The Technologies That Keep UA Ahead

- 3. What Makes UA’s Innovation Strategy Different

- 4. Comparison: Basic Fabrics vs UA-Level Performance Fabrics

- 5. What Brands Can Learn From UA’s Innovation Model

- FAQs

- Partnering With FuKi Gymwear

Quick Answer

Under Armour invests in performance fabric innovation because it is the brand’s core identity, its strongest competitive advantage, and the primary reason athletes choose UA over lifestyle-first brands.

Fabric innovation helps UA deliver:

- Better cooling

- Stronger compression

- Faster recovery

- Weather control

- More durable training gear

💬 From my OEM experience, the brands that innovate fabrics—not just designs—are the ones that survive long-term competition.

1. Why Under Armour Still Prioritizes Fabric Innovation

Here are the strategic reasons behind UA’s commitment to performance materials:

✔ 1. Performance differentiation

UA is strongest when it serves serious athletes.

✔ 2. Loyal athlete customer base

Its compression and cooling gear creates repeat buyers.

✔ 3. Fabric science cannot be copied easily

Designs can be imitated—fabric engineering cannot.

✔ 4. Margin advantage

High-tech fabrics allow premium pricing.

✔ 5. Seasonal versatility

UA sells year-round due to HeatGear®, ColdGear®, and ISO-Chill®.

💬 UA’s biggest enemy is “sameness.” Innovation keeps it original.

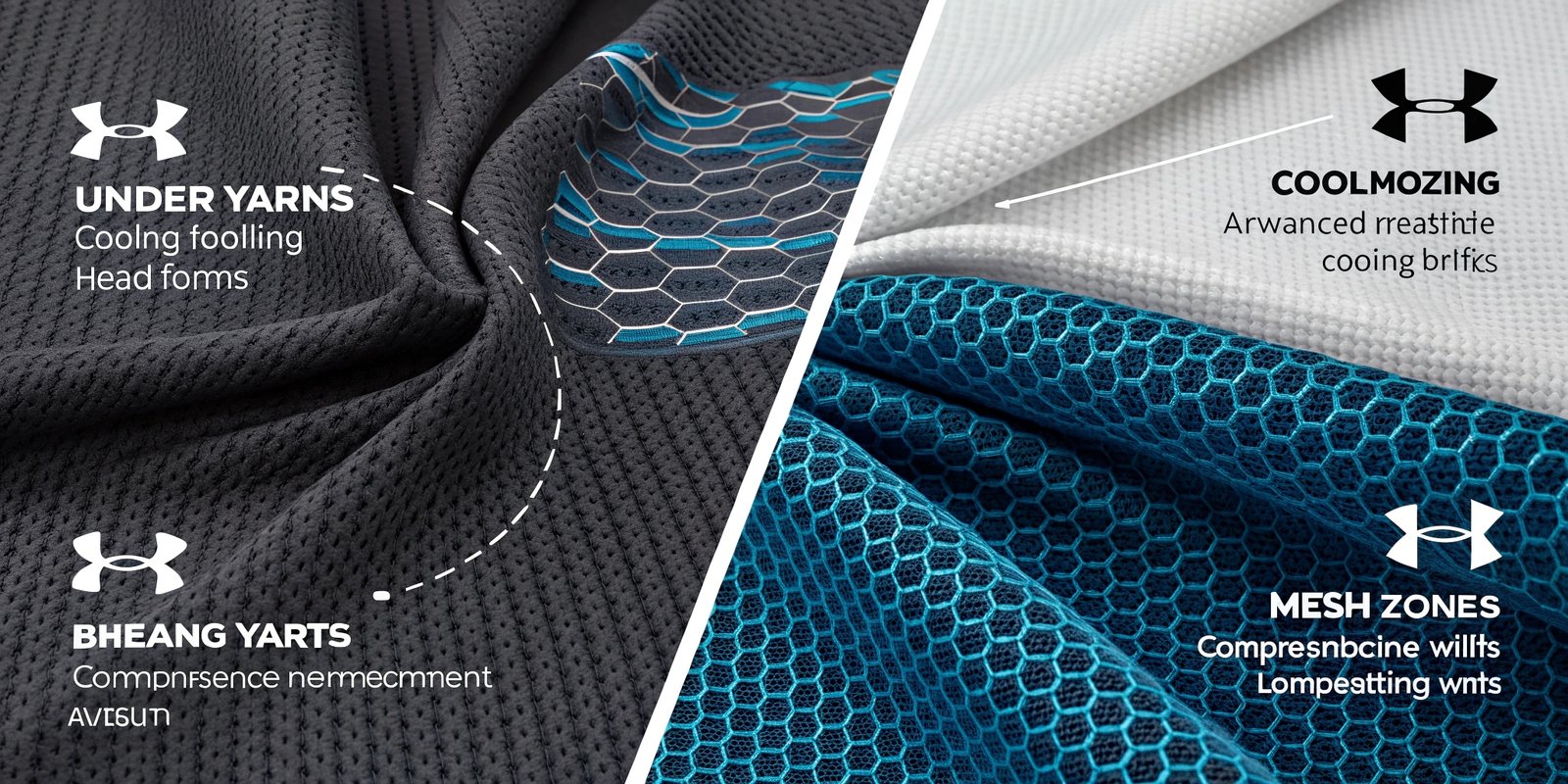

2. The Technologies That Keep UA Ahead

| UA Technology | Function | Why It Matters |

|---|---|---|

| HeatGear® | Sweat control + cooling | Essential for summer training |

| ColdGear® | Heat retention | Key for winter markets |

| ISO-Chill® | Cooling yarns reduce skin temp | Ideal for runners/outdoor |

| Compression tech | Muscle stability | Fewer injuries + better performance |

| UA RUSH™ | Mineral-infused recovery | Premium recovery apparel |

💬 Most brands stop at “moisture-wicking.” UA goes far beyond that.

3. What Makes UA’s Innovation Strategy Different

Under Armour is not just adding features—it engineers systems.

🔹 System-based design

Cooling, compression, and ventilation all work together.

🔹 Material + pattern integration

Fabrics are developed specifically for their panel placement.

🔹 Real athlete feedback

UA relies heavily on actual training data from runners, lifters, and teams.

🔹 Long-term R&D partnerships

UA invests in yarn innovation, not just fabric mills.

💬 Most brands buy fabrics. UA helps invent them.

4. Comparison: Basic Fabrics vs UA-Level Performance Fabrics

| Feature | Standard Fabric | UA-Level Fabric |

|---|---|---|

| Moisture-wicking | Basic chemical finish | Engineered capillary flow |

| Stretch | 4-way spandex | Targeted compression mapping |

| Temperature control | None | Cooling or thermal yarns |

| Durability | Moderate | High-abrasion tested |

| Breathability | Simple mesh | Zoned ventilation |

💬 UA fabrics are engineered for training, not just comfort.

5. What Brands Can Learn From UA’s Innovation Model

Here’s what smaller brands can apply immediately:

✔ Start with fabric, not design

Let the material define the function.

✔ Use testing standards

Stretch recovery, cooling tests, abrasion tests — all matter.

✔ Build signature fabric stories

Like HeatGear® or ISO-Chill®.

✔ Offer multiple climate-based ranges

Hot, cold, and transitional weather apparel.

✔ Partner with technical OEM factories

The right factory can elevate your entire product line.

💬 Innovation isn’t expensive — guessing is expensive. Testing saves brands.

FAQs

Q1: Why is UA so committed to performance fabric?

Because performance is its strongest identity and competitive differentiator.

Q2: Can small brands develop similar fabrics?

Yes—with the right OEM partners and clear functional goals.

Q3: What areas should brands innovate first?

Cooling, stretch recovery, and moisture management.

Q4: Is fabric innovation costly?

It costs more upfront but increases product value and repeat purchases.

Partnering With FuKi Gymwear

If your brand wants to build performance-focused activewear that competes with Under Armour,

👉 FuKi Gymwear can help you engineer the right materials and designs.

Why brands choose us:

- 🧵 Cooling yarns, compression knits, and technical blends

- 🚀 Fast sampling + low MOQs

- 🌡️ Performance testing options

- 🎽 Support for athletes, runners, and training brands

💬 Performance fabrics create performance brands—and FuKi Gymwear helps you build both.