As someone who works directly with OEM factories producing training apparel, performance tops, and compression gear, I often get asked:

“Where is Under Armour made today?”

This guide explains UA’s current manufacturing countries, what each region specializes in, and how the brand keeps quality consistent worldwide — written in a simple, beginner-friendly way with real industry insight.

Table of Contents

- Quick Answer

- 1. Where Under Armour Produces Now

- 2. What Each Country Specializes In

- 3. Why Under Armour Uses a Multi-Country Strategy

- 4. How UA Maintains Quality Across Factories

- FAQs

- Related Links

Quick Answer

Under Armour is currently made in Vietnam, China, Indonesia, Jordan, Cambodia, the Philippines, and a few smaller sourcing regions.

UA chooses factories based on technical fabric capability, cost balance, production speed, and long-term reliability — not just low labor cost.

External references:

- UA Official Site: https://www.underarmour.com

- UA Help (Product Info): https://www.underarmour.com/en-us/help

1. Where Under Armour Produces Now

Based on OEM factory benchmarks and updated sourcing trends:

Primary Production Hubs

- Vietnam → Training apparel, leggings, compression gear

- China → Technical fabrics, seamless, engineered base layers

- Indonesia → Footwear + cushioned midsoles

- Jordan → Team sports apparel

- Cambodia → Lightweight knits, T-shirts

- Philippines → Performance tops

OEM Insight:

Vietnam and China remain UA’s strongest partners for advanced performance gear due to their knitting, lamination, and compression-tech expertise.

2. What Each Country Specializes In

| Country | Strengths | Typical UA Products |

|---|---|---|

| Vietnam | Precise stitching, strong QC, scalable volume | Leggings, compression tops |

| China | Advanced fabric mills, seamless tech, bonding | HeatGear, base layers |

| Indonesia | Footwear midsole molding | UA running shoes |

| Jordan | Large uniform factories | Team jerseys |

| Cambodia | Lightweight knit specialists | Training tees |

| Philippines | Skilled technical operators | Performance tops |

Takeaway:

UA matches product type with factory capability, which is why fit and quality remain consistent.

3. Why Under Armour Uses a Multi-Country Strategy

✔ Diversified supply chain

Reduces risk from delays and geopolitical issues.

✔ Access to specialized machinery

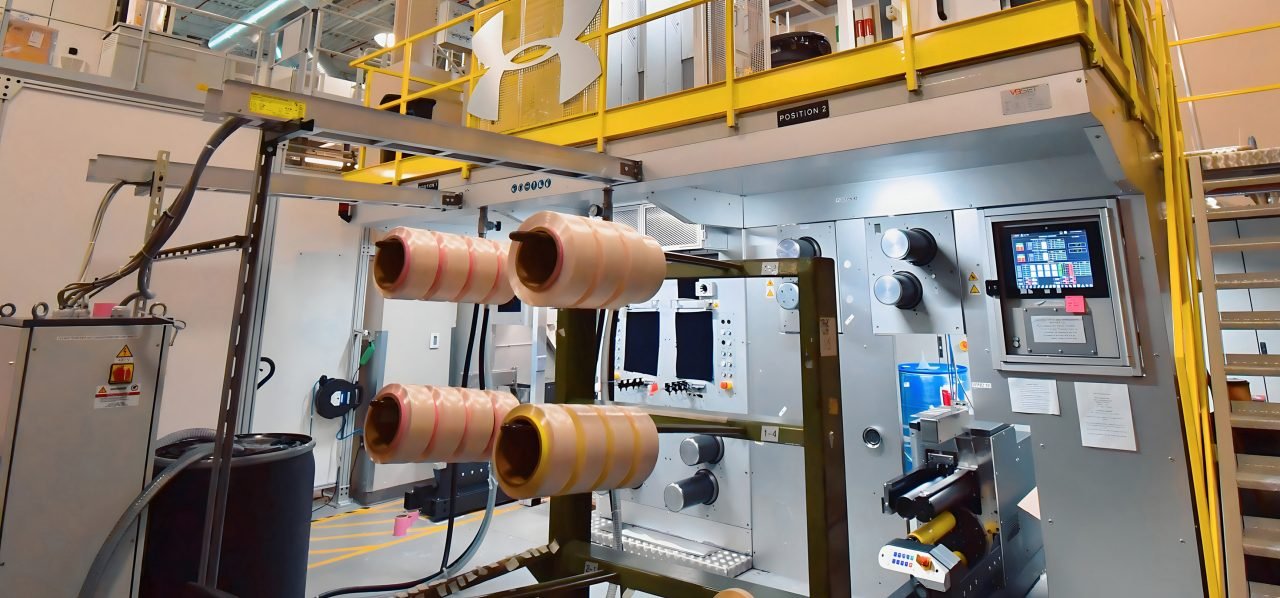

Seamless knitting, heat-transfer bonding, compression shaping.

✔ Cost + quality balance

UA competes in the mid-premium market, so production must be efficient without sacrificing performance.

✔ Faster product cycles

Multi-region sourcing shortens development and delivery time.

4. How UA Maintains Quality Across Factories

From my first-hand OEM experience:

UA uses consistent global standards:

- strict fabric tests (stretch recovery, moisture-wicking, pilling)

- size-spec enforcement through tech packs and fit blocks

- multi-step prototype approval

- stitching rules for compression gear

- third-party audits for compliance

OEM Insight:

Compression gear’s “tight feel” is intentional and engineered — not a sizing mistake.

FAQs

Q1: Is all Under Armour still made in Asia?

Mostly yes, but footwear and uniforms use a wider geographic mix.

Q2: Does UA make anything in the USA?

Very limited — mostly innovation/testing, not mass production.

Q3: Does manufacturing country affect UA quality?

Not significantly. UA’s QC system keeps specs consistent across regions.

Q4: Why is Vietnam so important to UA?

It has the strongest balance of cost, skill, and large production lines for performance apparel.

Related Links

- Under Armour Official: https://www.underarmour.com

- UA New Arrivals: https://www.underarmour.com/en-us/c/new-arrivals

- OEM / Activewear Manufacturing Support: https://fukigymwear.com