Puma manufacturing, activewear production, global supply chain, OEM apparel sourcing, FuKi GymwearPuma is one of the world’s biggest sportswear brands — but unlike what many people assume, Puma doesn’t rely on a single country for production.

Instead, the brand uses a global manufacturing network to balance cost, speed, sustainability, and product variety.

From my experience working with OEM activewear factories, Puma’s sourcing strategy is a great example of how big brands use multiple regions to maintain both quality and production flexibility.

This article explains where Puma manufactures, and what new or growing activewear brands can learn from its approach.

Table of Contents

- Quick Answer

- 1. Puma Produces in Multiple Countries, Not Just One

- 2. Why Puma Relies Heavily on Asia for Production

- 3. How Puma Chooses Manufacturing Locations

- 4. What New Activewear Brands Can Learn From Puma

- FAQs

- Partnering With FuKi Gymwear

Quick Answer

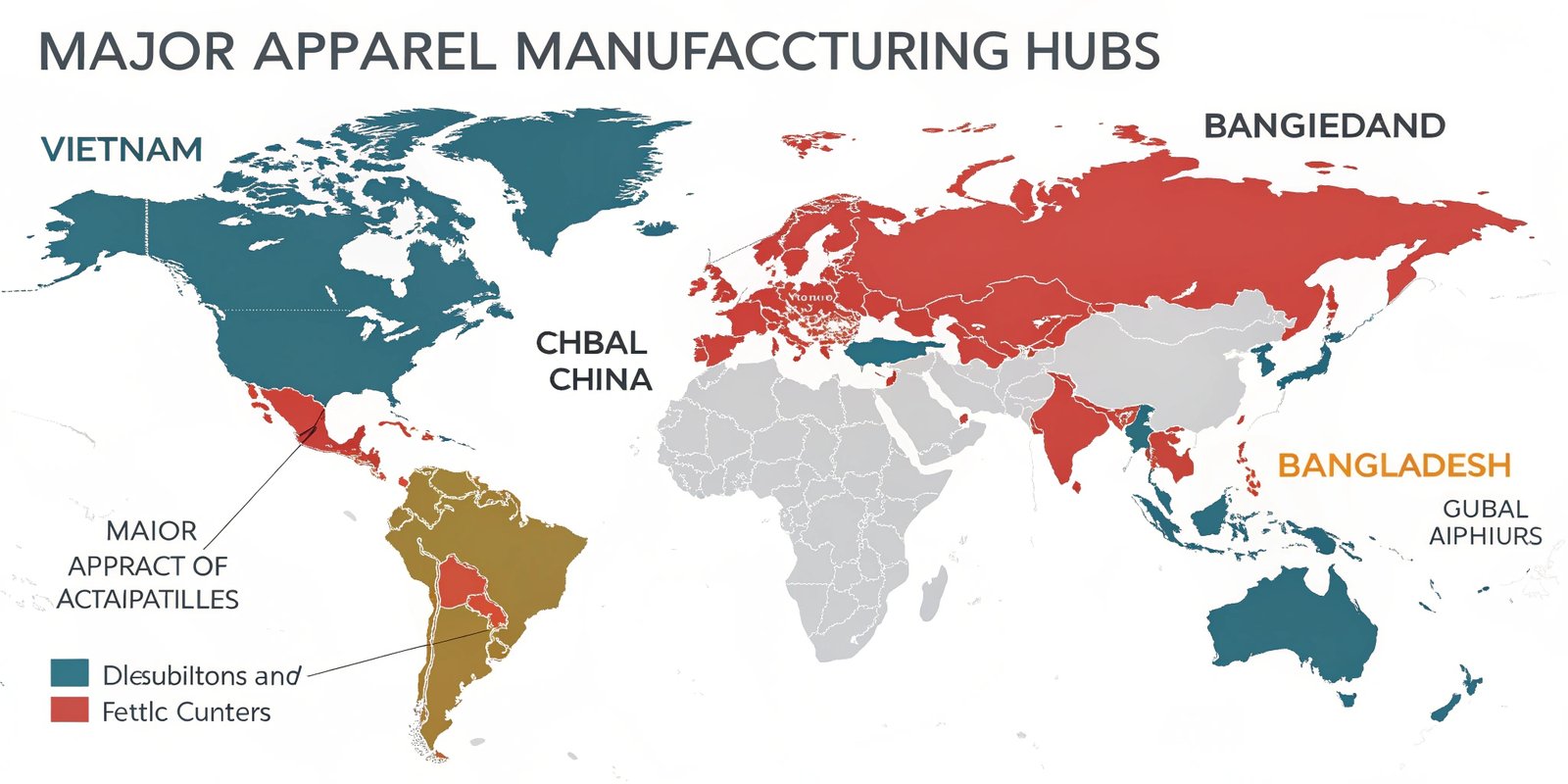

Puma manufactures in Asia, Europe, and the Americas, with most clothing produced in Vietnam, China, Bangladesh, Cambodia, and Turkey.

These regions offer the right balance of material sourcing, skilled labor, cost control, and large-scale capacity.

💬 From my OEM experience:

Most major activewear brands diversify production to avoid risk — Puma follows this strategy extremely well.

1. Puma Produces in Multiple Countries, Not Just One

Puma uses a broad network of factories around the world.

Main apparel manufacturing regions include:

- Vietnam

- China

- Bangladesh

- Cambodia

- Turkey

- India

- Sri Lanka

Why use multiple regions?

Because it gives Puma:

- cost flexibility

- faster turnaround

- access to specialty fabrics

- diversified supply-chain risks

- region-specific expertise (e.g., seamless, knitwear, outerwear)

OEM Insight

The most scalable activewear brands today do not rely on a single country — they build multi-region capabilities early.

2. Why Puma Relies Heavily on Asia for Production

Asia remains Puma’s largest manufacturing base because the region has:

✔ High technical capability

Factories in Vietnam, China, Sri Lanka, and Cambodia specialize in:

- performance fabrics

- seamless knitting

- bonded construction

- precision stitching

✔ Competitive labor cost

This keeps Puma’s price point accessible for global consumers.

✔ Proximity to material mills

Especially:

- nylon mills

- polyester mills

- dyeing and finishing houses

✔ Strong logistics infrastructure

Asia’s export systems are optimized for fast replenishment.

💬 The combination of skill + cost + capacity makes Asia ideal for activewear production.

3. How Puma Chooses Manufacturing Locations

Puma selects factories based on several operational priorities.

Key factors include:

- Fabric specialization (e.g., seamless, knit, woven)

- Compliance certifications

- Sustainability standards

- Labor conditions and social audits

- Production capacity

- Cost efficiency

- Shipment routes and lead time

Comparison Table

| Region | Strengths | Typical Products |

|---|---|---|

| Vietnam | High skill, stable quality | Training apparel, outerwear |

| China | Material access, tech capability | Performance fabrics, seamless |

| Bangladesh | Strong cost advantage | T-shirts, basics, large volume |

| Cambodia | Lightweight knits | Leggings, sports bras |

| Turkey | Near-shoring for Europe | Lifestyle apparel |

| Sri Lanka | Precision & performance | Sports bras, compression wear |

💬 Puma’s strategy shows that each region has clear strengths — smart brands utilize them accordingly.

4. What New Activewear Brands Can Learn From Puma

Here are actionable lessons for OEM-based activewear founders:

✔ Lesson 1: Start in Asia for performance apparel

Great for leggings, bras, seamless, and trainingwear.

✔ Lesson 2: Build multi-region manufacturing as you grow

It reduces:

- risk

- lead-time pressure

- overdependence on one supplier

✔ Lesson 3: Choose factories based on capability, not cost

Better to pick:

- correct fabric machines

- fit consistency

- technical experience

Rather than only chasing cheap pricing.

✔ Lesson 4: Use factories that support sustainability

Buyers increasingly expect:

- recycled fabric options

- OEKO-TEX certifications

- chemical compliance

- transparent audits

OEMs like ours help brands meet these standards.

✔ Lesson 5: Think long-term sourcing early

Puma’s model proves that strong brands plan years ahead, not months.

FAQs

Q1: Is all Puma clothing made in Asia?

No — Asia is the largest hub, but Puma also produces in Europe and the Americas.

Q2: Does Puma own its factories?

No, like most global brands, it works with independent OEM manufacturers.

Q3: Why doesn’t Puma manufacture in the U.S.?

Because costs are significantly higher, especially for performance fabrics.

Q4: Do smaller brands need multiple regions like Puma?

Not at first. Start with Asia, then diversify as your volume grows.

Partnering With FuKi Gymwear

If you want to build an activewear brand with strong sourcing flexibility and performance-ready fabrics — similar to Puma’s strategy — the right OEM partner is essential.

👉 FuKi Gymwear supports brands with:

- Performance fabrics for leggings & sports bras

- High-stretch seamless production

- Low MOQ for new brands

- Wide sourcing options in China & Vietnam

- Fast sampling

- Full quality testing support

💬 The more flexible your manufacturing model is, the faster your activewear brand can scale.