Table of Contents

- Quick Answer

- 1. What Really Affects the Cost of Custom Leggings?

- 2. Cost Breakdown: From Fabric to Final Product

- 3. Real Cost Ranges by Production Type

- 4. Top Manufacturers to Consider

- 5. Cost Comparison Table

- 6. How to Reduce Cost Without Killing Quality

- 7. FAQs

- Work With Fukigymwear

Quick Answer

If you're asking “How much does it cost to make custom leggings?”, the honest answer is:

👉 Anywhere from $8 to $35+ per piece, depending on fabric, quantity, customization, and where you manufacture.

From my experience working with fitness brands, most startups underestimate how fabric choice, MOQ, and construction details impact final cost. This guide breaks it down clearly so you can budget correctly — and avoid expensive mistakes.

1. What Really Affects the Cost of Custom Leggings?

Several factors directly influence production cost:

🔹 Fabric Selection

- Nylon-spandex blends cost more than polyester

- Brushed or compression fabrics increase cost

- Recycled materials add 10–20%

🔹 Pattern & Construction

- High-waist bands

- Seamless or contour stitching

- Hidden pockets or bonded seams

More construction = higher labor cost.

🔹 Order Quantity (MOQ)

Lower quantities increase per-unit pricing.

🔹 Country of Production

Labor, compliance, and logistics differ by region.

2. Cost Breakdown: From Fabric to Final Product

| Cost Component | Typical Range (USD) |

|---|---|

| Fabric | $3 – $8 |

| Cutting & Sewing | $3 – $6 |

| Printing / Dyeing | $1 – $3 |

| Labels & Packaging | $0.50 – $2 |

| Quality Control | $0.50 – $1 |

| Total Estimated Cost | $8 – $35+ |

These are factory-side costs, not retail prices.

3. Real Cost Ranges by Production Type

Private Label (Fastest & Cheapest)

- $8–$15 per unit

- Best for testing the market

- Limited customization

Custom OEM (Balanced)

- $15–$25 per unit

- Full fabric and fit control

- Best for growing brands

Premium Custom (Advanced)

- $25–$35+ per unit

- Custom fabric development

- Advanced construction & finishes

4. Top Manufacturers to Consider

1. Fukigymwear – Custom Activewear Manufacturer

Best for startups needing flexibility, low MOQ, and full customization.

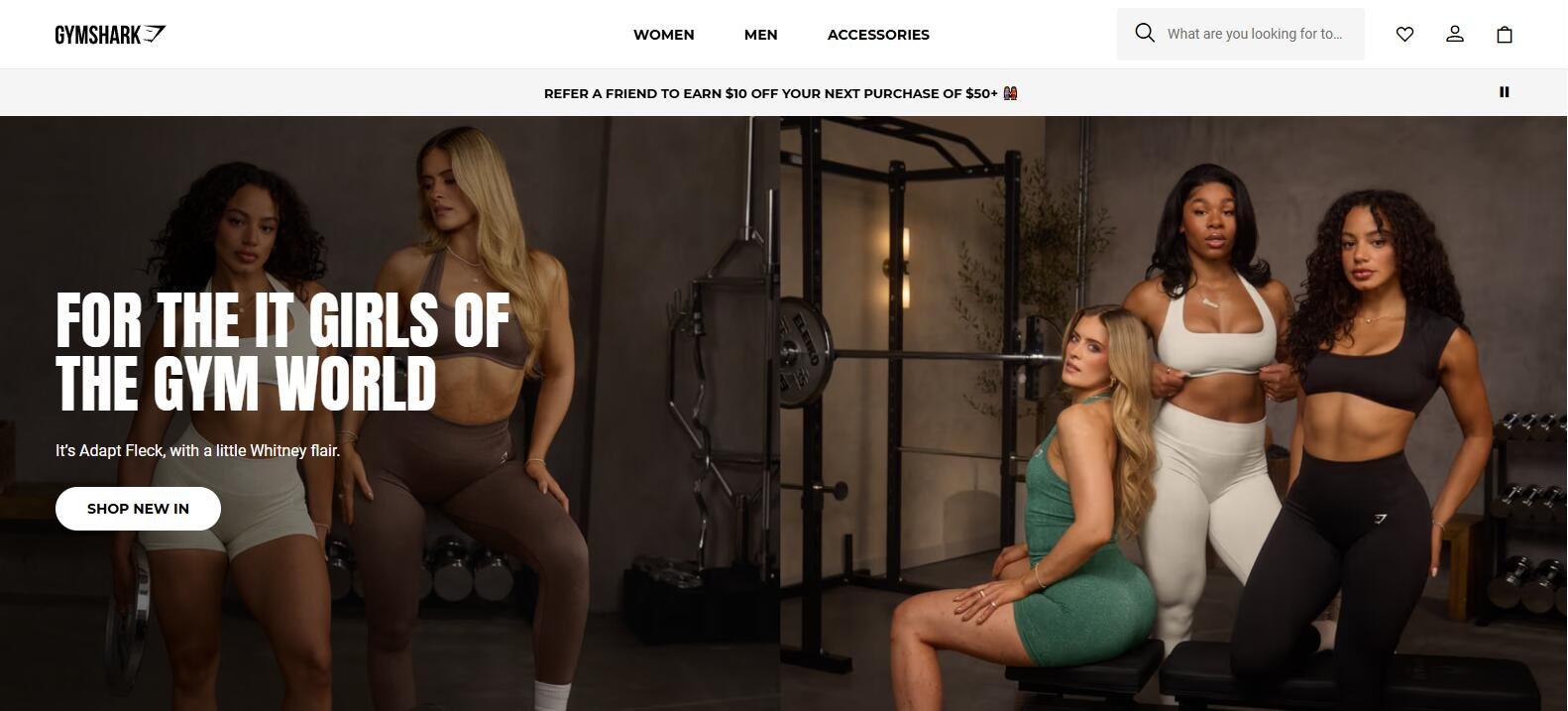

2. Gymshark – Performance Benchmark

👉 Gymshark

Great reference for performance quality and scalability.

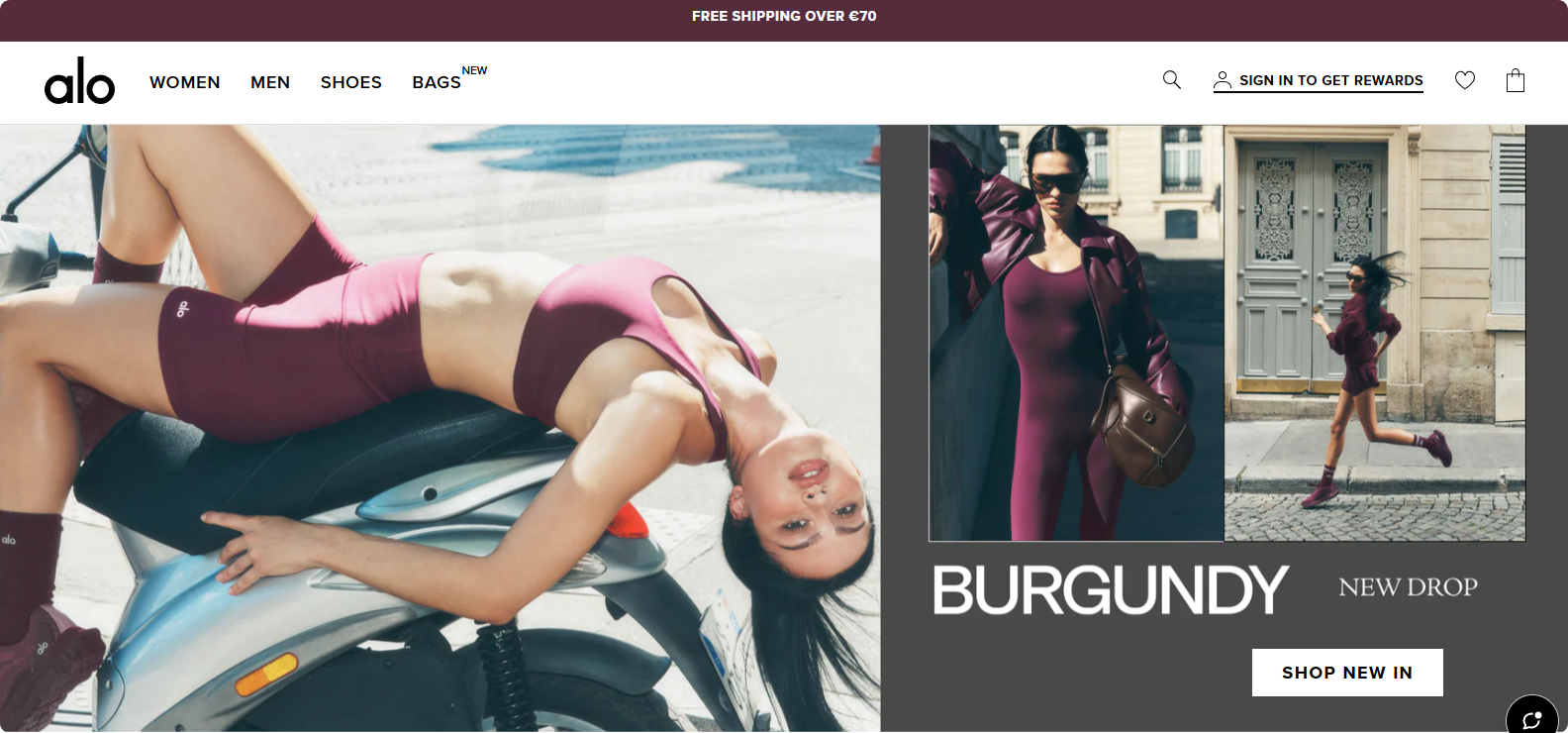

3. Alo Yoga – Premium Fashion Fit

👉 Alo Yoga

Best for fashion-forward and premium positioning.

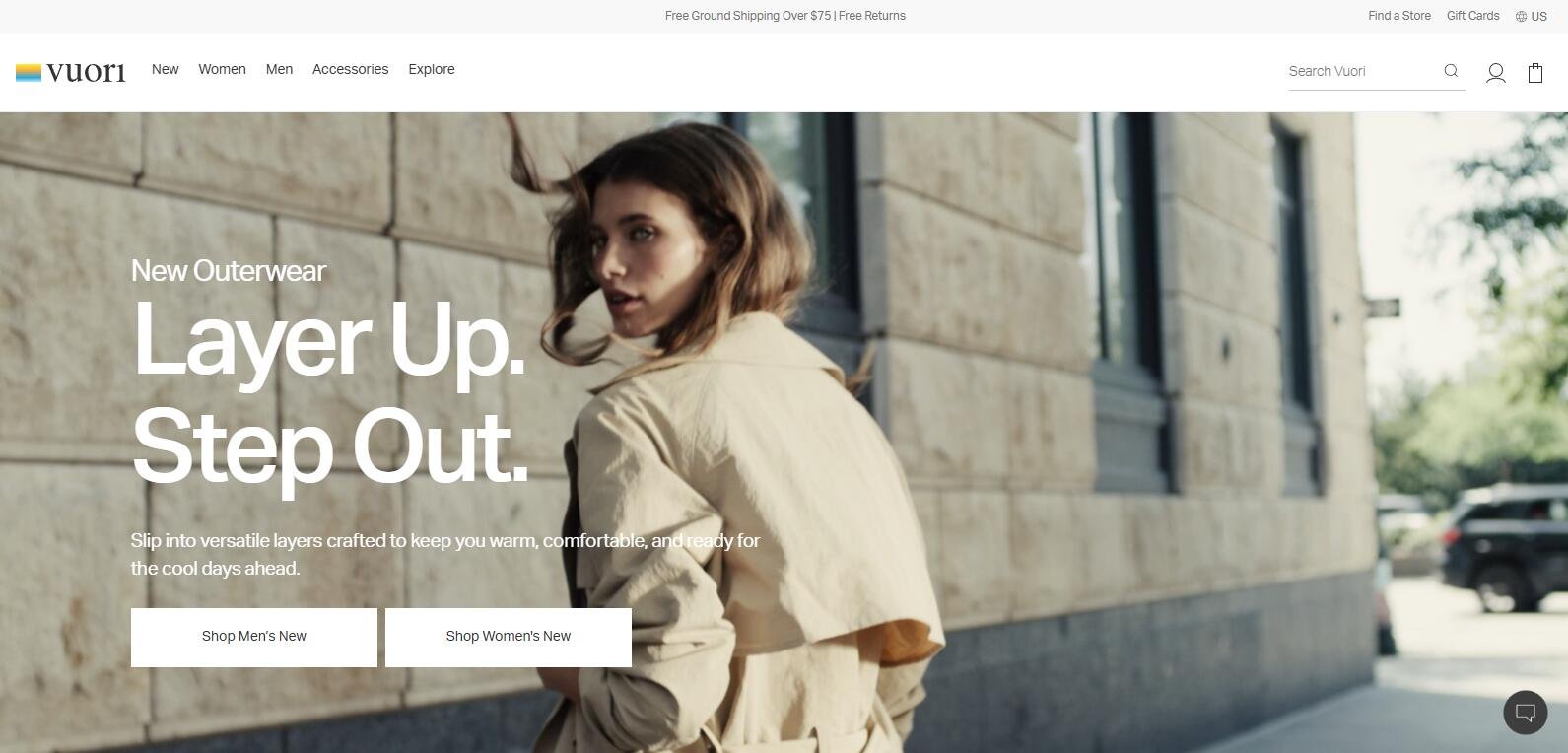

4. Vuori – High-End Comfort Wear

👉 Vuori

Known for comfort-focused performance apparel.

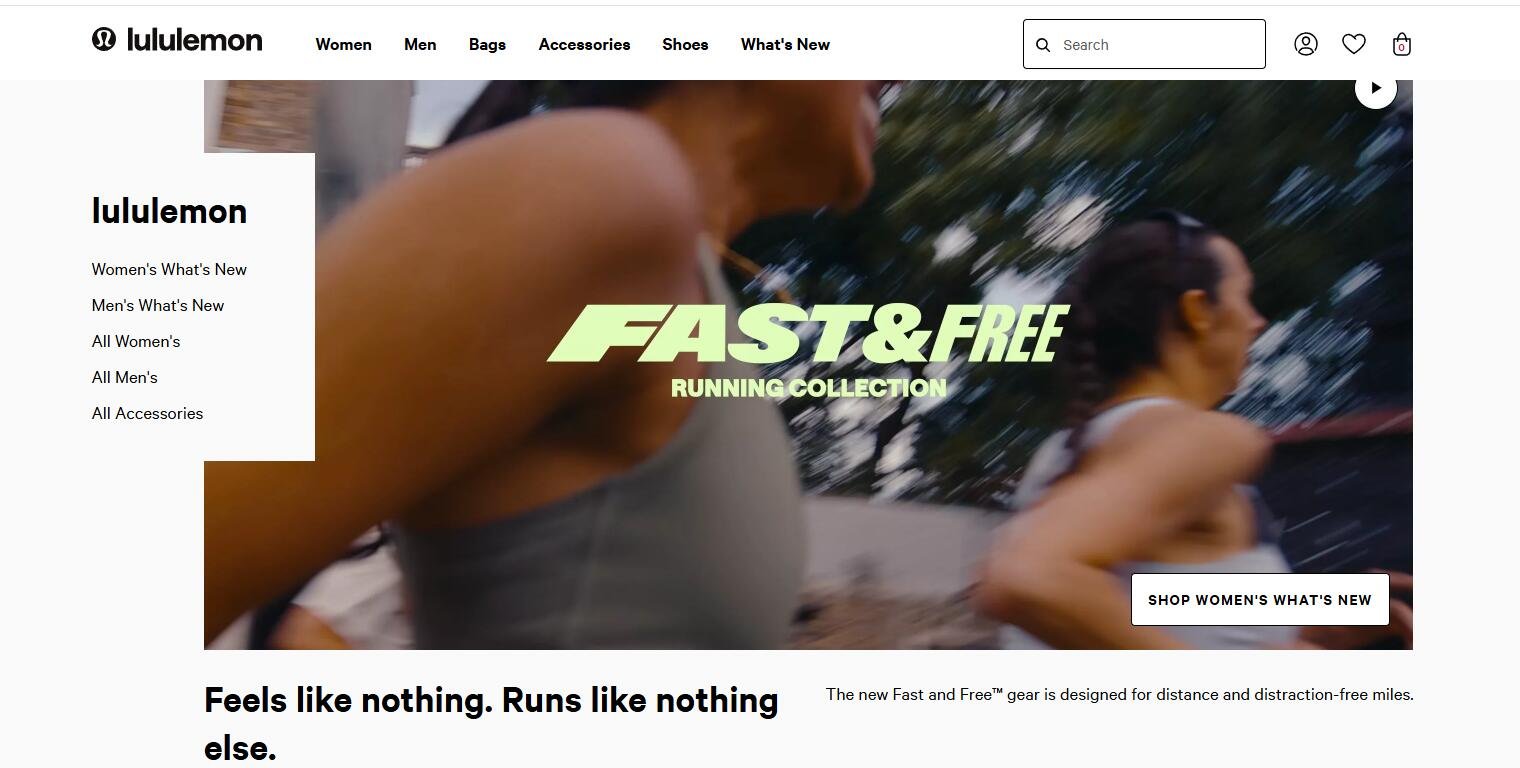

5. Lululemon – Technical Benchmark

Industry leader in fabric innovation and quality.

5. Cost Comparison Table

| Type | Cost/Unit | MOQ | Customization | Best For |

|---|---|---|---|---|

| Private Label | $8–$15 | Low | Limited | Testing market |

| Custom OEM | $15–$25 | Medium | High | Growing brands |

| Premium Custom | $25–$35+ | High | Full | Premium positioning |

6. How to Reduce Cost Without Killing Quality

✔ Choose proven fabrics

✔ Simplify seam construction

✔ Order fewer colors per style

✔ Increase quantity gradually

✔ Work with experienced OEMs

Smart planning beats cheap production.

7. FAQs

Q: What’s the cheapest way to make leggings?

Private label with standard fabrics and higher MOQs.

Q: Can I make high-quality leggings on a budget?

Yes—by choosing smart fabric blends and avoiding over-design.

Q: Is overseas manufacturing risky?

Not if you work with experienced suppliers and clear specs.

Work With Fukigymwear

If you want clear pricing, reliable quality, and a partner who understands activewear manufacturing:

We help brands design, sample, and produce leggings with confidence.