Table of Contents

- Quick Answer

- Why Brands Develop Custom Leggings

- My Experience Working With Factories

- Key Steps in Developing Custom Leggings

- Top Custom Leggings Factories (With Links)

- Factory Comparison Table

- How to Choose the Right Factory for Your Brand

- FAQs

- Work With Fukigymwear

Quick Answer

If you want to know how fitness brands develop custom leggings with factories, the process boils down to three pillars:

- Clarifying brand goals and performance requirements

- Iterative development (fabric → pattern → fit → sample)

- Quality control and production readiness

In my experience, successful brands treat leggings as engineered performance products, not simple fashion items — and that mindset shift changes everything.

Why Brands Develop Custom Leggings

Fitness leggings are no longer a commodity — they are a brand differentiator:

- Customers demand better fit, performance, and comfort

- Generic leggings lead to poor reviews and higher returns

- Custom design conveys brand identity (logo, style, materials)

- Repeat purchases depend on fit consistency

If you’ve ever launched a basic “off-the-shelf” style and seen returns spike, you’ll know why brands invest in custom development.

My Experience Working With Factories

Over the years, I’ve worked directly with factories to develop leggings for:

- Yoga and studio wear

- Functional training leggings

- High-compression performance tights

- Athleisure / lifestyle crossover designs

What I learned early on was simple:

The quality of your supplier relationship is just as important as your design idea.

You can have a great concept, but if you don’t communicate clearly with the factory on fit, fabric, and quality standards, the final product will miss expectations.

Key Steps in Developing Custom Leggings

1. Define Brand Position & Target Use

Ask yourself:

- Who is the end user? (yoga, gym, running, lifestyle)

- What performance attributes matter? (stretch, recovery, compression)

- What price point are you targeting?

Your answers will influence everything downstream — from fabric selection to fit construction.

2. Fabric Selection & Performance Requirements

Choosing fabric isn’t just about color and pattern. You must consider:

| Feature | What to Look For | Why It Matters |

|---|---|---|

| Stretch & Recovery | High elastane/spandex content | Comfort + longevity |

| Opacity | High coverage under stretch | Wear confidence |

| Moisture Management | Quick-dry fabrics | Sweat performance |

| Handfeel | Soft but supportive | Wearability |

Common performance blends include:

- Nylon + Elastane

- Polyester + Spandex

- Seamless knit constructions

Before bulk runs, always request swatches and test for opacity, shrinkage, and stretch recovery.

3. Pattern Development & Fit Testing

This is where many brands make mistakes.

Good patterns consider:

- Waist rise and curve

- Crotch depth and angle

- Knee and thigh shaping

- Ankle opening tension

Fit testing should include real movement:

- Squats

- Lunges

- Yoga stretches

I always tell brands: Fit creates loyalty. If the leggings don’t move well with the body, no amount of design will save them.

4. Sampling & Technical Refinement

Sampling stages usually include:

- Prototype sample

- Fit sample with edits

- Pre-production sample

- Size set samples (3–6 sizes)

At each stage, gather feedback from testers or models in your target niche.

This iterative loop saves you costly revisions later.

5. Production & Quality Control

Once the sample is approved:

- Confirm measurement tolerances

- Conduct inline inspections during sewing

- Check wash performance and stretch retention

A good factory will support final inspections before shipment and help troubleshoot common issues like seam twist or waistband rolling.

Top Custom Leggings Factories (With Links)

1. Fukigymwear – Performance Activewear OEM

Full-service factory specializing in custom leggings, gym wear, and private label development.

Best for: Performance brands and startups alike.

2. Activewear Manufacturer – Private Label Supplier

Offers custom activewear production with multiple fabric and fit options.

Best for: Brands launching or expanding performance collections. :contentReference[oaicite:0]{index=0}

3. Argus Apparel – USA Leggings OEM

Custom and private label leggings manufacturer with design, sampling, and production support for athletic and fashion brands.

Best for: Brands needing hands-on development and flexible production options. :contentReference[oaicite:1]{index=1}

4. Affix Apparel – Custom Leggings Supplier

Provides private-label leggings with low MOQs and premium customization.

Best for: Brands looking for advanced customization (prints, fabrics, sustainable options). :contentReference[oaicite:2]{index=2}

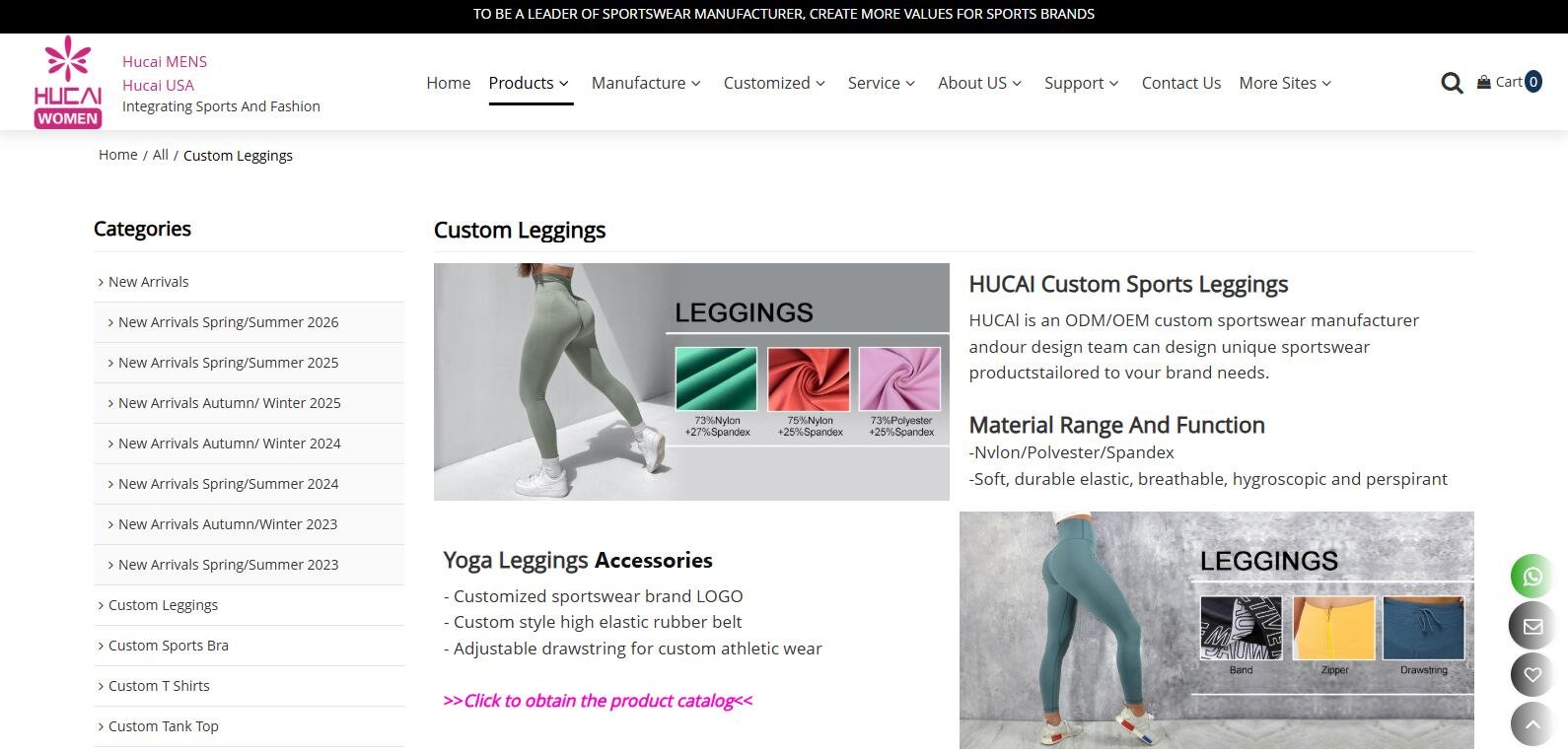

5. Hucai Sportswear – OEM Activewear Manufacturer

Experienced OEM factory offering one-stop leggings and activewear manufacturing for global brands.

Best for: Brands seeking competitive pricing and bulk production with quality control. :contentReference[oaicite:3]{index=3}

Factory Comparison Table

| Factory | MOQ | Customization | Strength |

|---|---|---|---|

| Fukigymwear | Low–Mid | ⭐⭐⭐⭐⭐ | Fabric + Fit |

| Activewear Manufacturer | Mid | ⭐⭐⭐⭐ | Private label |

| Argus Apparel | Mid | ⭐⭐⭐⭐ | USA OEM |

| Affix Apparel | Low–Mid | ⭐⭐⭐⭐ | Custom + prints |

| Hucai Sportswear | Mid–High | ⭐⭐⭐⭐ | Bulk production |

How to Choose the Right Factory for Your Brand

Here’s how I help brands make the decision:

- Budget-conscious startups: prioritize communication + sampling support

- Performance-first brands: prioritize fabric expertise + fit engineering

- Premium brands: emphasize quality control + wash testing

- Scaling brands: choose capacity + inline QC systems

Avoid choosing solely based on low cost — leggings manufacturing is technical and needs clarity at every step.

FAQs

Q: What is the typical MOQ for developing custom leggings?

A: Usually 100–300 units per style, depending on fabric and factory policies.

Q: Can I choose any fabric I want?

A: Yes — but always request swatch tests before bulk production.

Q: How long does the development process take?

A: Sampling takes 10–20 days; full production varies between 30–50 days.

Q: What is the biggest mistake brands make?

A: Not validating fit on real bodies before bulk runs.

Work With Fukigymwear

If you want to develop custom leggings with factories that understand performance and quality,

👉 Fukigymwear offers end-to-end support — from fabric selection and pattern engineering to sampling and production.

We help brands build leggings that customers trust, wear, and reorder.