Table of Contents

- Quick Answer

- What Private Label Sports Bra Production Really Means

- My Experience Working with Private Label Sports Bra Brands

- Key Elements in Private Label Sports Bra Production

- Step-by-Step: Private Label Sports Bra Production Process

- Common Mistakes Private Label Brands Make

- Private Label Sports Bra Manufacturers (With Links)

- Comparison Table

- How to Choose the Right Model for Your Brand

- FAQs

- Work With Fukigymwear

Quick Answer

Private label sports bra production allows brands to launch faster by using existing factory patterns and structures, while customizing fabrics, colors, branding, and fit details.

From my experience, private label works best when brands:

- Start with proven structures

- Customize selectively (not everything at once)

- Focus on consistency before innovation

This guide explains how private label sports bras are actually produced — and how brands can avoid common pitfalls.

What Private Label Sports Bra Production Really Means

In factory terms, private label sports bras mean:

- Using existing base patterns or silhouettes

- Customizing branding, colorways, and materials

- Skipping full pattern development from scratch

This reduces:

- Development cost

- Sampling time

- Technical risk

Private label is often the smartest entry point for new activewear brands.

My Experience Working with Private Label Sports Bra Brands

I’ve worked with private label brands at different stages:

- New fitness startups launching first collections

- Influencer brands testing demand

- Boutique labels expanding into activewear

The most common misconception:

Private label means low quality or no customization.

In reality, strong private label programs are built on proven engineering, not shortcuts.

Key Elements in Private Label Sports Bra Production

Even with private label, several elements must be controlled:

| Element | Why It Matters |

|---|---|

| Base pattern | Determines support & fit |

| Fabric choice | Affects comfort & durability |

| Elastic quality | Controls long-term support |

| Branding | Defines perceived value |

| QC standards | Protects consistency |

Private label simplifies development — it does not remove responsibility.

Step-by-Step: Private Label Sports Bra Production Process

1. Select a Proven Base Style

Factories usually offer:

- Light-support yoga bras

- Medium-support training bras

- High-support performance bras

Choose based on your target customer and activity.

2. Customize Materials & Colors

Common private label customizations:

- Fabric upgrades

- Color matching

- Lining changes

- Elastic strength adjustments

Small material changes can significantly improve performance.

3. Apply Branding & Labels

Typical branding options:

- Heat transfer logos

- Woven labels

- Care labels

- Custom packaging

Branding must be tested for wash durability.

4. Sampling & Fit Confirmation

Even private label requires:

- Size confirmation

- Motion testing

- Wash testing

Skipping this step leads to high return rates.

5. Bulk Production & QC

Reliable factories perform:

- Inline QC checks

- Measurement audits

- Elastic tension testing

Private label still needs professional QC.

Common Mistakes Private Label Brands Make

- Over-customizing at the start

- Ignoring elastic quality

- Skipping fit testing

- Choosing suppliers only by price

Private label works best when brands build step by step.

Private Label Sports Bra Manufacturers (With Links)

1. Fukigymwear – Private Label Sports Bra Manufacturer

Offers structured private label sports bra programs with flexible MOQ and stable quality control.

Best for: Brands launching or scaling private label activewear.

2. Affix Apparel – Private Label Activewear Supplier

Supports low-MOQ private label sports bras.

Best for: Startups testing the market.

3. Argus Apparel – USA-Based Private Label Manufacturer

Domestic private label production with development support.

Best for: Brands focusing on USA-made positioning.

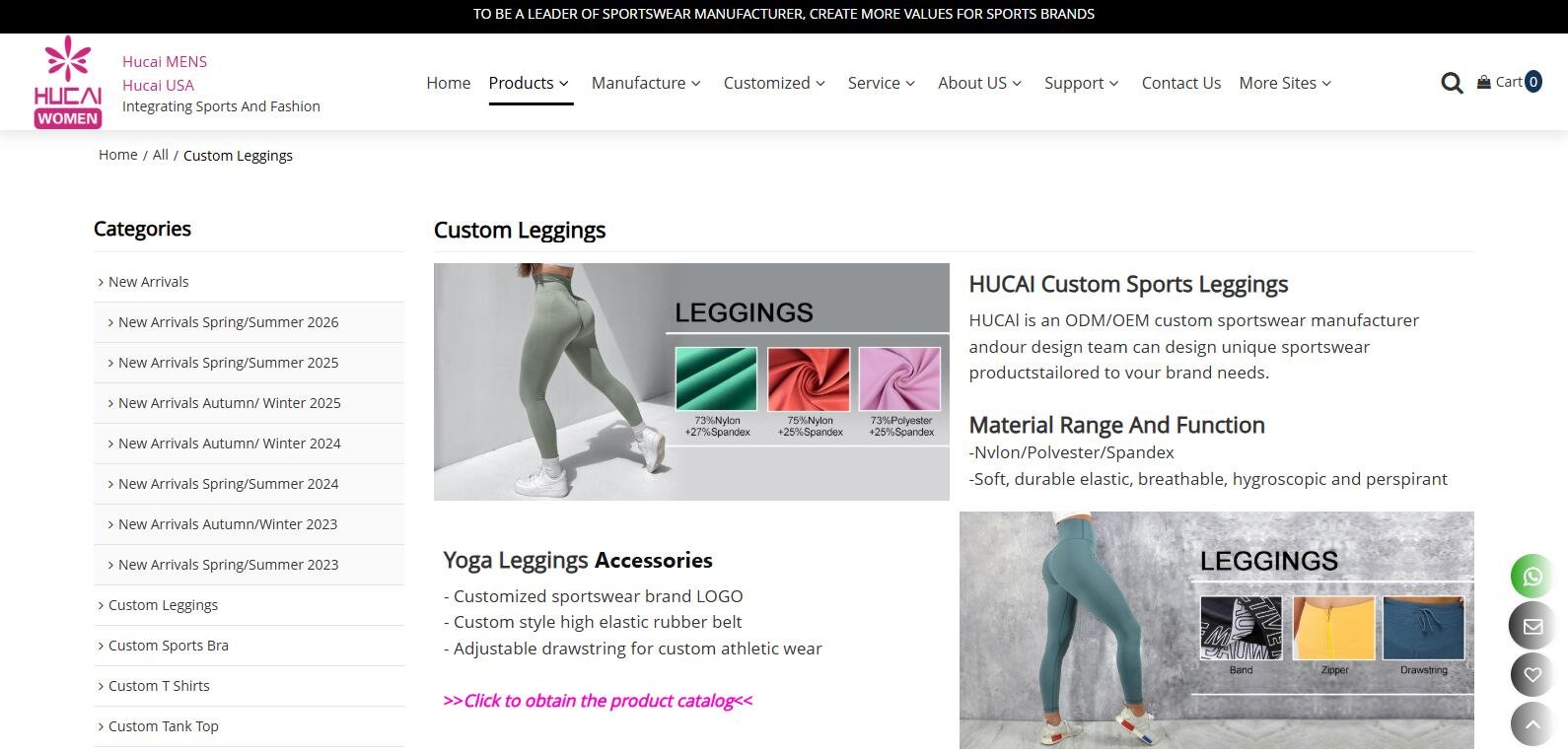

4. Hucai Sportswear – OEM & Private Label Factory

OEM factory offering private label and bulk programs.

Best for: Cost-efficient production.

5. Alanic – Global Sportswear Manufacturer

👉 Alanic

Large-scale private label and OEM manufacturing.

Best for: Established brands expanding globally.

Comparison Table

| Manufacturer | Private Label Strength | MOQ | Best For |

|---|---|---|---|

| Fukigymwear | Strong | Low–Mid | New & growing brands |

| Affix Apparel | Medium | Low | Market testing |

| Argus Apparel | Medium | Mid | USA production |

| Hucai Sportswear | Medium | Mid–High | Bulk programs |

| Alanic | Standardized | High | Global scale |

How to Choose the Right Model for Your Brand

- New brands: start with proven private label styles

- Growing brands: gradually customize materials and fit

- Premium brands: add structural and material upgrades

- Scaling brands: focus on consistency and reorders

Private label is a strategy — not a limitation.

FAQs

Q: Is private label suitable for premium brands?

A: Yes, if materials and QC standards are upgraded.

Q: Can private label sports bras be customized later?

A: Absolutely. Many brands start private label, then move to full OEM.

Q: What is the typical MOQ for private label sports bras?

A: Usually 100–300 pcs per style.

Work With Fukigymwear

If you’re planning private label sports bra production and want speed without sacrificing quality,

👉 Fukigymwear offers structured private label programs designed for long-term brand growth.

We help brands launch confidently — and scale responsibly.