Table of Contents

- Quick Answer

- What “Custom Hoodie OEM” Really Means

- What I’ve Learned Building Activewear Hoodies

- The Real OEM Development Flow

- Design Choices That Define Cost & Performance

- Where Most Brands Fail

- Recommended Custom Hoodie Manufacturers

- Factory Comparison Table

- How to Choose the Right OEM Partner

- FAQs

- Work With Fukigymwear

Quick Answer

Custom hoodie OEM for activewear is not about copying a street hoodie and adding your logo.

It’s about building a performance layer that:

- Keeps stable weight from sample to bulk

- Holds shape after wash

- Moves with the body during training

- Feels premium without being heavy

- Reorders without drifting

From my experience, hoodie programs fail when brands treat them like fashion items.

Great OEM partners treat hoodies as functional equipment.

What “Custom Hoodie OEM” Really Means

Most brands think OEM means:

Send a reference → Approve a sample → Place an order

In real manufacturing, OEM includes:

- Fabric performance testing (GSM, shrinkage, pilling)

- Pattern engineering for movement

- Sampling & wear trials

- Pre-production (PP) system setup

- Bulk workflow control

- Reorder standardization

A hoodie is a system, not a style.

What I’ve Learned Building Activewear Hoodies

Across dozens of brands, I see two outcomes:

Weak OEM

- Sample feels light, bulk feels heavy

- Hood collapses after wash

- Sleeves restrict movement

- Reorders feel different

Strong OEM

- Fabric weight locked

- Shoulder and armhole engineered

- Hoods hold shape

- Every batch matches

The difference is never geography.

It’s whether the factory runs on process.

The Real OEM Development Flow

1. Fabric Qualification

Factories verify:

- GSM tolerance

- Shrinkage rate

- Pilling resistance

- Stretch recovery

This prevents “sample good, bulk bad.”

2. Pattern Engineering

Activewear hoodies require:

- Balanced shoulder slope

- Armhole depth for motion

- Tapered waist shaping

- Hood volume control

Streetwear blocks rarely work for training.

3. Sampling & Wear Testing

Expect:

- 2–3 prototype rounds

- Wash testing

- Arm-lift and stretch tests

- Zipper and rib durability checks

Mirror approval is not performance approval.

4. Pre-Bulk Lock

Strong OEMs lock:

- Fabric lot

- Pattern version

- Stitch density

- Rib and cuff specs

This prevents drift.

5. Bulk Production & QC

Good factories:

- Check 1 per bundle

- Compare to golden sample

- Control rib choose and hood shape

That’s how hoodies stay consistent.

Design Choices That Define Cost & Performance

| Choice | Impact |

|---|---|

| French terry vs fleece | Weight & breathability |

| Brushed inner | +10–15% cost |

| Double-layer hood | +8–12% labor |

| Shaped side panels | Better fit, higher cost |

| YKK zipper | +$0.40–$0.80 |

| Branded rib | MOQ pressure |

Most “expensive” hoodies are expensive because of construction decisions, not factory margin.

Where Most Brands Fail

| Mistake | Result |

|---|---|

| Choosing only by price | Heavy, stiff fabric |

| No wash testing | Shrinkage |

| Using streetwear blocks | Poor movement |

| Over-designing first drop | Delays |

| No bulk controls | Inconsistency |

Activewear hoodies must perform, not just look premium.

Recommended Custom Hoodie Manufacturers

1. Fukigymwear – Activewear Hoodie OEM

Low-MOQ OEM with fabric testing, fit tuning, and reorder stability.

Best for: Brands launching or scaling performance hoodies.

2. MAS Holdings – Performance Apparel Engineering

Global leader in technical activewear manufacturing.

Best for: Premium and performance-first programs.

3. Hansae – Global Apparel Manufacturing

👉 Hansae

Large-scale OEM platform for global brands.

Best for: Retail and regional scale.

4. Makalot – Sportswear Production

👉 Makalot

Well-known for sports and lifestyle apparel manufacturing.

Best for: Mid-to-large volume programs.

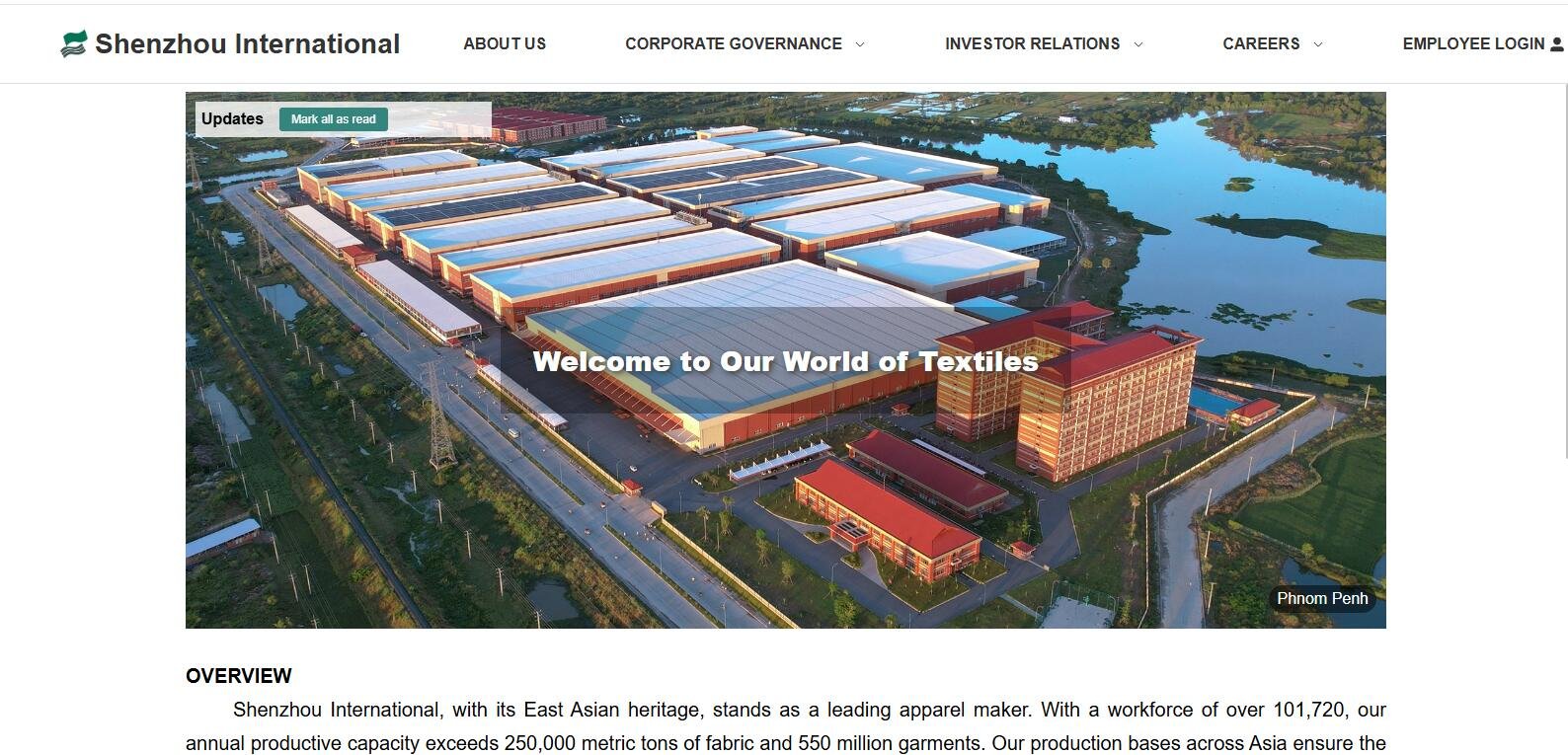

5. Shenzhou International – Knitwear Specialist

One of the world’s largest knitwear manufacturers.

Best for: High-volume hoodie programs.

Factory Comparison Table

| Factory | MOQ | Technical Depth | Best Use |

|---|---|---|---|

| Fukigymwear | 100–300 | High | New brands |

| MAS Holdings | 1,000+ | Very High | Premium lines |

| Hansae | 1,000+ | High | Retail scale |

| Makalot | 800+ | Medium–High | Lifestyle activewear |

| Shenzhou International | 2,000+ | High | Mass volume |

How to Choose the Right OEM Partner

- First hoodie program → Fukigymwear

- Premium performance → MAS Holdings

- Retail scale → Hansae

- Lifestyle crossover → Makalot

- Large-scale volume → Shenzhou International

Choose based on fabric control and workflow clarity, not just price.

FAQs

Q: What’s a normal MOQ for custom hoodies?

A: 300–1,000 pcs per style is common.

Q: How long does development take?

A: 3–5 weeks for samples, then 30–45 days for bulk.

Q: Can small brands start OEM hoodies?

A: Yes—partners like Fukigymwear support low MOQs.

Work With Fukigymwear

If you want to build custom activewear hoodies that balance

performance, comfort, and bulk consistency—

👉 Fukigymwear

offers OEM and private label hoodie manufacturing with low MOQ, fabric control, and long-term production systems.