Table of Contents

- Quick Answer

- What “Factory Workflow” Really Means

- What I’ve Learned Inside Hoodie Factories

- The End-to-End Hoodie Workflow

- Where Quality Is Won or Lost

- Recommended Activewear Hoodie Manufacturers

- Factory Workflow Comparison Table

- How to Choose the Right Factory Partner

- FAQs

- Work With Fukigymwear

Quick Answer

An activewear hoodie factory workflow is not just “cut and sew.”

It’s a system that determines whether your hoodie:

- Keeps the same weight from sample to bulk

- Holds shape after wash

- Moves comfortably during training

- Matches across reorders

- Ships on time without surprises

From my experience, hoodie problems rarely come from sewing.

They come from missing controls between steps.

Great factories win on process discipline, not just machines.

What “Factory Workflow” Really Means

Most brands imagine:

Fabric in → Hoodie out

A professional activewear factory actually runs a chain of systems:

- Fabric inspection & testing

- Pattern and size control

- Pre-production setup (PP)

- Cutting & line balancing

- Inline quality control

- Final inspection & packing

- Reorder standardization

Each step either protects your brand—or exposes it.

What I’ve Learned Inside Hoodie Factories

After visiting and working with many floors, I see two types:

Unstructured floors

- No GSM tolerance

- Operators “adjust” patterns

- QC only at the end

- Every order feels new

System-driven floors

- Fabric tested before cutting

- Digital patterns locked

- QC at every stage

- Reorders mirror originals

The second type is how brands scale.

The End-to-End Hoodie Workflow

1. Fabric Intake & Testing

Factories verify:

- GSM range

- Shrinkage rate

- Pilling resistance

- Stretch recovery

This prevents “sample light, bulk heavy.”

2. Pattern Lock & PP Meeting

- Final pattern version is frozen

- Size set is approved

- Stitch specs are explained

- Golden sample is issued

PP is where mistakes are prevented.

3. Cutting

- Fabric is relaxed

- Layers are aligned

- Markers control usage

- Tolerances are enforced

Bad cutting ruins perfect sewing.

4. Sewing Line Setup

- Operations are sequenced

- Stitch density is fixed

- Hood and rib tension are standardized

Operators follow systems, not memory.

5. Inline QC

Good factories:

- Check 1 per bundle

- Measure key points

- Stop line on deviation

Problems are fixed before they multiply.

6. Final QC & Packing

- Compare to golden sample

- Verify size ratios

- Inspect trims and branding

- Pack by order spec

Only then does shipping begin.

Where Quality Is Won or Lost

| Stage | Risk If Skipped |

|---|---|

| Fabric testing | Weight drift |

| PP meeting | Misinterpretation |

| Cutting control | Size variance |

| Inline QC | Batch defects |

| Reorder spec | Inconsistency |

Quality is created before the first seam.

Recommended Activewear Hoodie Manufacturers

1. Fukigymwear – Process-Driven Hoodie OEM

Low-MOQ OEM with fabric testing, fit control, and reorder systems.

Best for: Brands building their first performance hoodies.

2. MAS Holdings – Performance Apparel Systems

Global leader in structured performance manufacturing.

Best for: Premium and technical programs.

3. Hansae – Global Apparel Manufacturing

👉 Hansae

Large-scale OEM platform for global brands.

Best for: Retail and regional scale.

4. Makalot – Sportswear Production

👉 Makalot

Well-known for sports and lifestyle apparel manufacturing.

Best for: Mid-to-large volume programs.

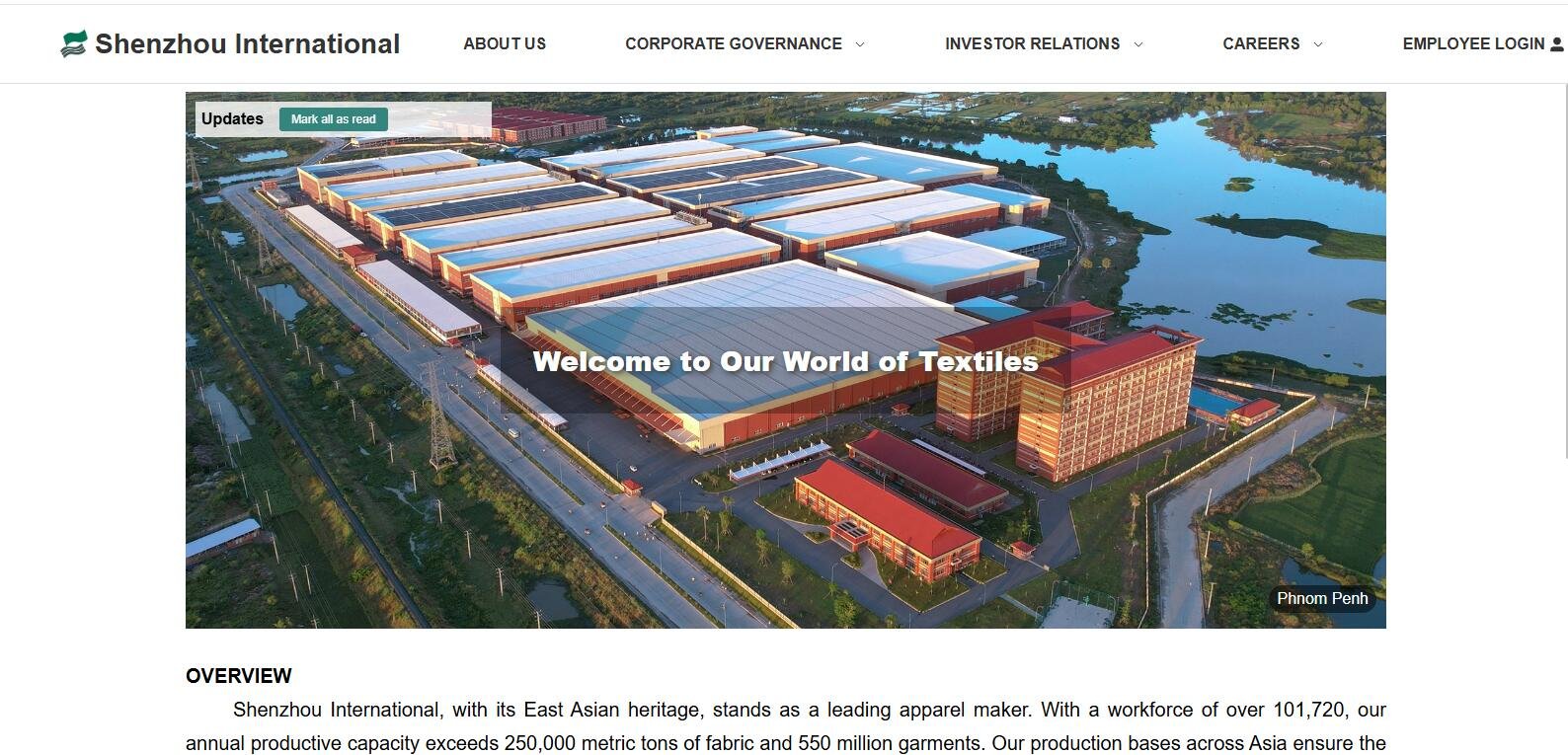

5. Shenzhou International – Knitwear Specialist

One of the world’s largest knitwear manufacturers.

Best for: High-volume hoodie programs.

Factory Workflow Comparison Table

| Factory | MOQ | Process Depth | Best Use |

|---|---|---|---|

| Fukigymwear | 100–300 | High | New brands |

| MAS Holdings | 1,000+ | Very High | Premium lines |

| Hansae | 1,000+ | High | Retail scale |

| Makalot | 800+ | Medium–High | Lifestyle activewear |

| Shenzhou International | 2,000+ | High | Mass volume |

How to Choose the Right Factory Partner

- First hoodie program → Fukigymwear

- Premium performance → MAS Holdings

- Retail scale → Hansae

- Lifestyle crossover → Makalot

- Large-scale volume → Shenzhou International

Choose based on workflow clarity, not just price.

FAQs

Q: How long does the full hoodie workflow take?

A: 3–5 weeks for development, 30–45 days for bulk.

Q: Can small brands access real factory systems?

A: Yes—partners like Fukigymwear support low MOQs.

Q: What’s the biggest risk in hoodie production?

A: Skipping pre-production controls.

Work With Fukigymwear

If you want hoodies that stay consistent from

sample → bulk → reorder, you need a factory that runs on systems.

👉 Fukigymwear

offers OEM and private label hoodie manufacturing with fabric testing, workflow control, and low MOQ support.