Table of Contents

- Quick Answer

- What Scaling Sports Bra Manufacturing Really Means

- My Experience Scaling Sports Bra Production with OEMs

- Key Challenges When Scaling Sports Bras

- How OEM Partners Enable Scalable Sports Bra Production

- Step-by-Step: Scaling Sports Bra Manufacturing with OEMs

- Sports Bra OEM Manufacturers (With Links)

- Comparison Table

- How to Choose the Right OEM Partner for Scaling

- FAQs

- Work With Fukigymwear

Quick Answer

Scaling sports bra manufacturing is not about ordering more units — it’s about building the right OEM partnership.

From my experience, brands successfully scale sports bras only when OEM partners can:

- Lock support structure and patterns

- Control elastic and fabric consistency

- Maintain QC at higher volumes

- Support repeatable reorders

This guide explains how fitness brands scale sports bra production with OEM partners — without losing fit, support, or quality.

What Scaling Sports Bra Manufacturing Really Means

For most brands, scaling means:

- Moving from 200–500 pcs → 1,000–5,000+ pcs

- Expanding from one support level to multiple

- Repeating best-selling styles across seasons

At scale, sports bras fail faster than leggings if systems are weak — because support tolerance is much tighter.

My Experience Scaling Sports Bra Production with OEMs

I’ve worked with brands scaling:

- Yoga and studio bras

- Medium-support training bras

- High-support running and HIIT bras

The most common mistake I see:

Brands scale order quantity before locking structure, pattern, and materials.

When sports bras scale without locked systems, issues multiply — especially elastic fatigue and support inconsistency.

Key Challenges When Scaling Sports Bras

| Challenge | Why It Happens |

|---|---|

| Support inconsistency | Elastic & pattern drift |

| Size instability | Unlocked grading |

| Higher return rates | Poor support in larger sizes |

| QC overload | Manual inspection fails at volume |

OEM partners must solve these before volume increases.

How OEM Partners Enable Scalable Sports Bra Production

Strong OEM partners provide:

- Pattern locking and version control

- Elastic and fabric lot tracking

- Inline QC systems

- Repeatable production workflows

Scaling is a system upgrade, not a quantity change.

Step-by-Step: Scaling Sports Bra Manufacturing with OEMs

1. Lock Support Architecture

- Fix support level (light / medium / high)

- Lock strap width, elastic strength, and lining

2. Freeze Pattern & Size Grading

- No structural changes mid-scale

- Adjust only after full production cycles

3. Validate Materials at Bulk Level

- Test elastic rebound

- Test fabric stretch recovery after wash

4. Move QC Inline

- First-piece approval per line

- Support-specific QC checkpoints

5. Plan Reorders Early

- Reserve fabric and elastic

- Maintain consistent dye lots

Scaling works when reorders are planned, not reactive.

Sports Bra OEM Manufacturers (With Links)

1. Fukigymwear – Sports Bra OEM Partner

Experienced in scaling sports bra production with locked support systems and repeatable QC.

Best for: Brands scaling from startup to established volume.

2. Affix Apparel – Custom Sports Bra OEM

Flexible MOQ and private label programs.

Best for: Brands testing scale in stages.

3. Argus Apparel – USA-Based Sports Bra Manufacturer

Domestic production with development support.

Best for: Brands prioritizing USA-made scaling.

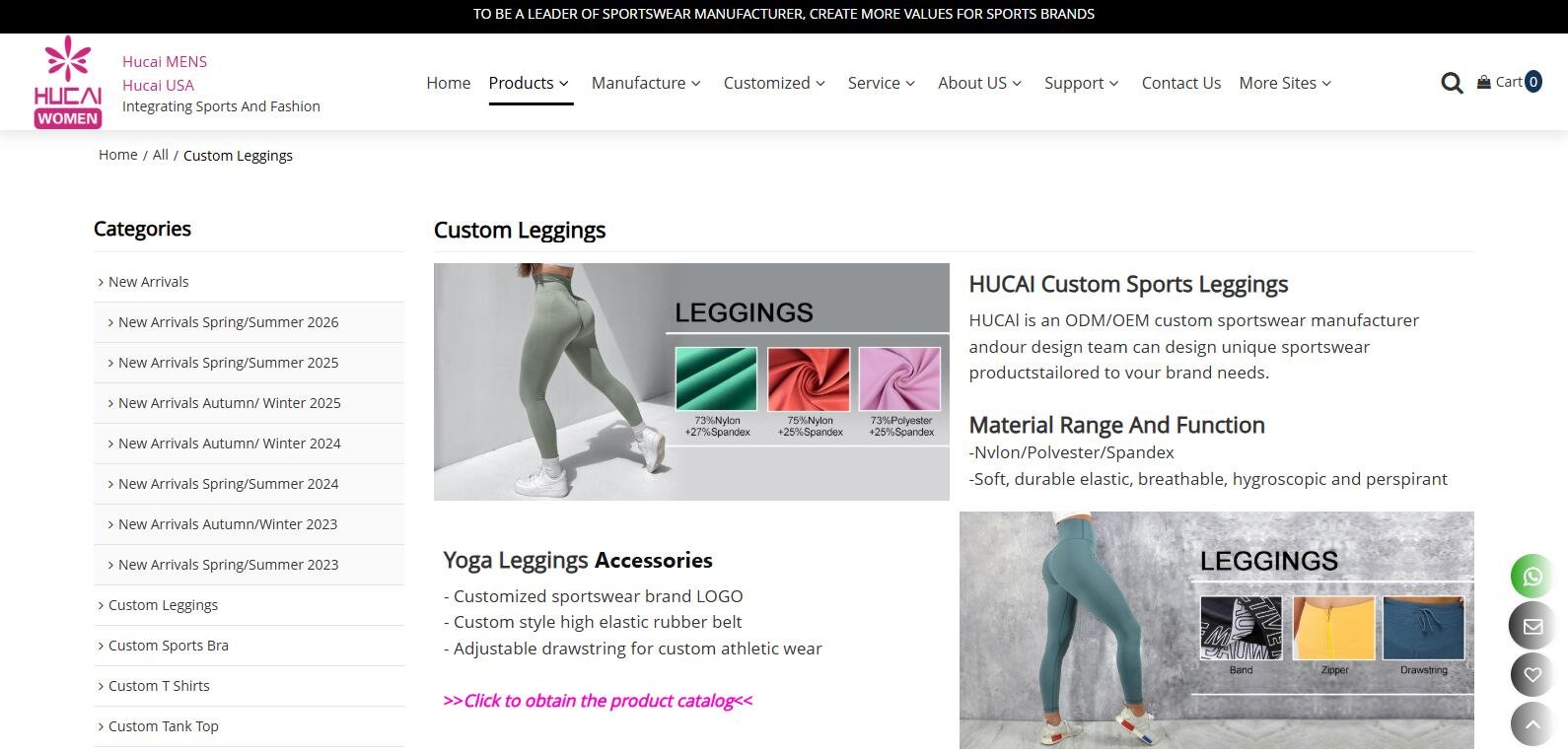

4. Hucai Sportswear – OEM Activewear Factory

OEM factory capable of bulk sports bra production.

Best for: Cost-efficient volume growth.

5. Alanic – Global Sportswear Manufacturer

👉 Alanic

Large-scale sportswear manufacturing with global reach.

Best for: International expansion.

Comparison Table

| OEM Partner | Scaling Strength | MOQ | Best Use Case |

|---|---|---|---|

| Fukigymwear | Pattern & QC control | Low–Mid | Long-term scaling |

| Affix Apparel | Flexibility | Low | Test-to-scale brands |

| Argus Apparel | Domestic systems | Mid | USA positioning |

| Hucai Sportswear | Cost efficiency | Mid–High | Bulk orders |

| Alanic | Capacity | High | Global scale |

How to Choose the Right OEM Partner for Scaling

Choose OEM partners based on your stage:

- Early scale: flexibility and sampling support

- Growth stage: QC systems and reorder stability

- Mature brands: capacity and global logistics

Scaling fails when OEM partners are chosen only by price.

FAQs

Q: When should brands start scaling sports bra production?

A: After support structure and fit are proven across at least one reorder.

Q: What breaks first when scaling sports bras?

A: Elastic rebound and size consistency.

Q: Can OEM partners help reduce risk when scaling?

A: Yes — strong OEMs build systems that protect consistency.

Work With Fukigymwear

If you’re ready to scale sports bra manufacturing with a reliable OEM partner,

👉 Fukigymwear supports brands with structured development, locked patterns, and scalable production systems.

We help you scale without sacrificing support, fit, or brand trust.