Table of Contents

- Quick Answer

- Why Sports Bras Are Harder to Manufacture Than Leggings

- My Experience Manufacturing Custom Sports Bras

- What Defines a High-Quality Sports Bra

- Step-by-Step: Custom Sports Bra Manufacturing Process

- Top Custom Sports Bra Manufacturers (With Links)

- Comparison Table

- How to Choose the Right Factory for Your Brand

- FAQs

- Work With Fukigymwear

Quick Answer

Manufacturing custom sports bras is primarily about support engineering, not just fabric or style.

From my experience, brands struggle with sports bras because they underestimate:

- Support structure

- Elastic behavior

- Cup and strap interaction

This guide explains how factories actually manufacture sports bras — and what brands must control to avoid fit failures, returns, and negative reviews.

Why Sports Bras Are Harder to Manufacture Than Leggings

Compared to leggings, sports bras:

- Carry more weight and tension in smaller areas

- Require more precise elastic control

- Must fit across cup size, not just waist/hip

A leggings fit issue might cause discomfort.

A sports bra fit issue causes lack of support or pain — which leads to immediate returns.

My Experience Manufacturing Custom Sports Bras

I’ve worked with brands producing:

- Light-support yoga bras

- Medium-support training bras

- High-support running and HIIT bras

- Longline and cropped bra tops

The biggest mistake I see:

Brands design sports bras visually, not structurally.

A good-looking bra that lacks proper internal support will always fail in real workouts.

What Defines a High-Quality Sports Bra

A high-quality sports bra must balance support, comfort, and durability.

| Element | What Matters | Why It’s Critical |

|---|---|---|

| Fabric | Stretch recovery | Prevents bounce |

| Elastic | Strength + rebound | Maintains support |

| Lining | Stability | Shapes and controls |

| Seams | Placement & strength | Prevents irritation |

| Straps | Width & elasticity | Distributes load |

Support comes from structure, not compression alone.

Step-by-Step: Custom Sports Bra Manufacturing Process

1. Support Level & Intended Use

Factories first define:

- Light support (yoga, pilates)

- Medium support (training, cycling)

- High support (running, HIIT)

Support level affects:

- Fabric GSM

- Elastic strength

- Strap width

- Internal structure

2. Fabric, Lining & Elastic Selection

Common materials:

- Nylon + Spandex (outer shell)

- Power mesh (internal support)

- Brushed lining (comfort)

- Reinforced elastic (underbust)

Elastic quality is often the deciding factor between good and bad sports bras.

3. Pattern Engineering & Size Grading

Sports bras require:

- Cup-aware pattern shaping

- Correct underbust tension

- Strap angle optimization

Poor grading leads to:

- Digging straps

- Loose underbust

- Insufficient support in larger sizes

4. Sampling, Fit Testing & Revisions

Sampling stages include:

- Prototype

- Fit sample

- Support test sample

- Size set samples

Fit testing should include:

- Jumping

- Running

- Stretch and recovery checks

5. Production, QC & Consistency

QC focus points:

- Elastic stretch and rebound

- Strap strength testing

- Seam stress testing

- Size measurement tolerance

Sports bras require tighter QC than leggings.

Top Custom Sports Bra Manufacturers (With Links)

1. Fukigymwear – Performance Sports Bra OEM

Specializes in custom sports bras with controlled support engineering and fit development.

Best for: Performance and private label activewear brands.

2. Affix Apparel – Custom Activewear Manufacturer

Offers low-MOQ custom sports bra manufacturing.

Best for: Startups testing multiple designs.

3. Argus Apparel – USA-Based Manufacturer

Provides design, sampling, and domestic production support.

Best for: Brands prioritizing USA-made sports bras.

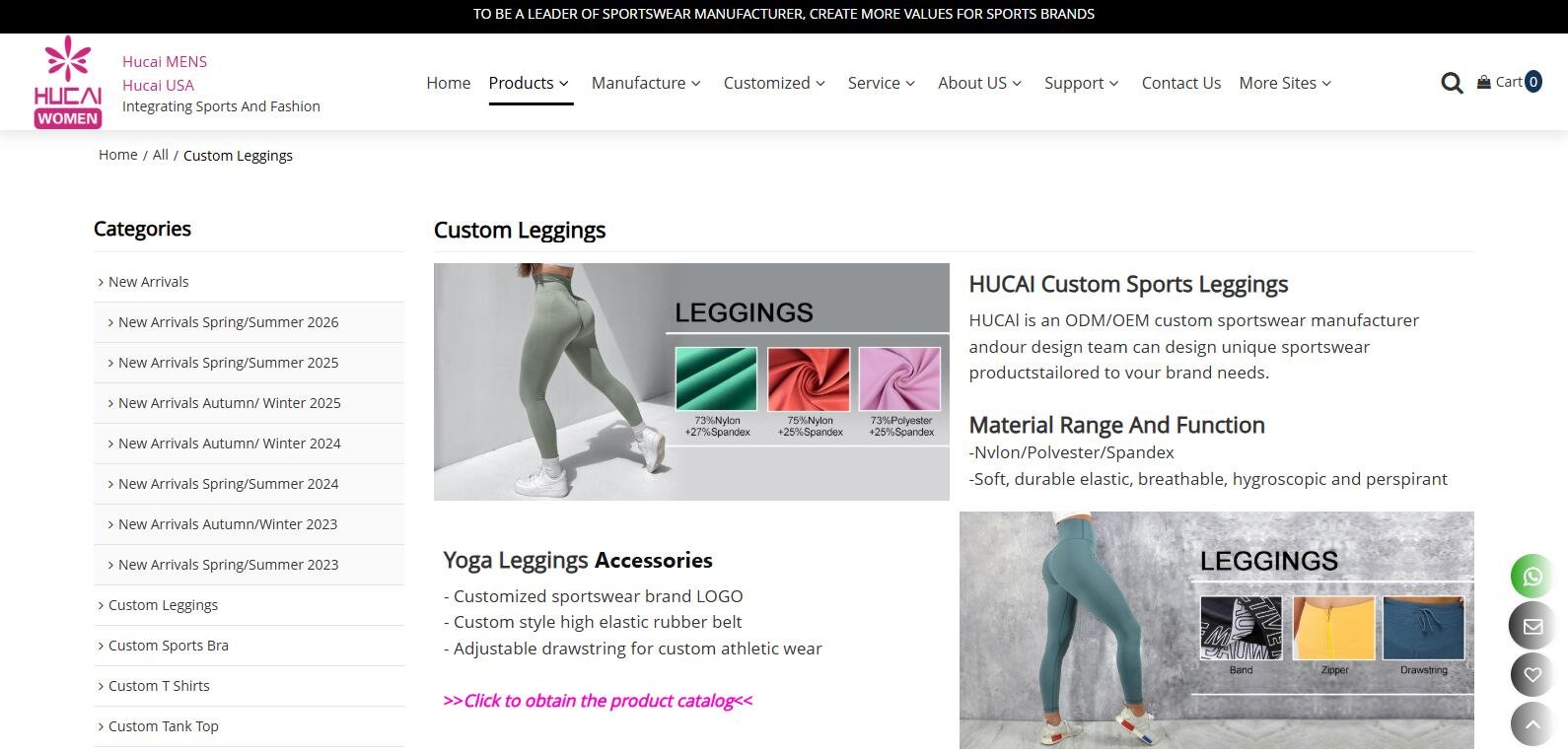

4. Hucai Sportswear – OEM Activewear Factory

One-stop OEM solution for sports bras and gym wear.

Best for: Brands scaling bulk production.

5. Alanic – Global Sportswear Manufacturer

👉 Alanic

Large-scale production with global capacity.

Best for: Established brands expanding internationally.

Comparison Table

| Manufacturer | MOQ | Strength | Best For |

|---|---|---|---|

| Fukigymwear | Low–Mid | Support engineering | Performance brands |

| Affix Apparel | Low | Custom flexibility | Startups |

| Argus Apparel | Mid | USA OEM | Domestic positioning |

| Hucai Sportswear | Mid–High | Cost efficiency | Bulk orders |

| Alanic | High | Scale & capacity | Global brands |

How to Choose the Right Factory for Your Brand

- Yoga / studio brands: prioritize comfort and fabric feel

- Training brands: prioritize elastic and support testing

- Premium brands: prioritize QC and consistency

- Scaling brands: prioritize capacity and repeatability

Choosing the wrong factory shows immediately in sports bras.

FAQs

Q: What is the MOQ for custom sports bras?

A: Typically 100–300 pcs per style depending on structure and materials.

Q: Are sports bras harder to manufacture than leggings?

A: Yes — they require more structural engineering and tighter QC.

Q: Can support level be customized?

A: Absolutely. Support level is defined at the pattern and elastic stage.

Work With Fukigymwear

If you’re developing custom sports bras and need a factory that understands support, fit, and consistency,

👉 Fukigymwear offers end-to-end manufacturing support — from development to bulk production.

We help brands build sports bras customers trust during real workouts.