Table of Contents

- Quick Answer

- Why Choosing the Right Leggings OEM Matters

- My Experience Evaluating Leggings OEM Manufacturers

- Core Capabilities Every Leggings OEM Must Have

- Key Criteria to Evaluate a Leggings OEM Manufacturer

- Top Leggings OEM Manufacturers (With Links)

- Comparison Table

- How to Choose the Right OEM for Your Brand Stage

- FAQs

- Work With Fukigymwear

Quick Answer

When choosing a leggings OEM manufacturer, focus on fabric performance, fit engineering, sampling discipline, and production consistency — not just price.

From my experience, most leggings failures happen because brands choose factories that are good at sewing, but not specialized in performance leggings development. This guide shows exactly what to look for before committing.

Why Choosing the Right Leggings OEM Matters

Leggings are one of the highest-risk products in activewear manufacturing.

A weak OEM partner often leads to:

- Sheer fabric under stretch

- Waistbands that roll or lose elasticity

- Inconsistent sizing between orders

- Increased returns and negative reviews

A strong OEM manufacturer solves these problems before bulk production.

My Experience Evaluating Leggings OEM Manufacturers

I’ve evaluated and worked with OEM factories producing:

- Gym and training leggings

- Yoga and studio leggings

- High-compression performance tights

- Private label activewear collections

What I learned quickly:

A factory that makes T-shirts well is not automatically a good leggings OEM.

Leggings require fabric behavior control, pattern precision, and disciplined QC. OEMs without this experience struggle as volumes grow.

Core Capabilities Every Leggings OEM Must Have

Before working with any OEM, I check for these fundamentals:

| Capability | Why It Matters |

|---|---|

| Fabric testing | Prevents opacity and recovery issues |

| Pattern engineering | Ensures fit consistency |

| Structured sampling | Reduces costly revisions |

| Inline QC | Protects bulk quality |

| Reorder stability | Enables brand scaling |

Without these, even a low MOQ OEM becomes risky.

Key Criteria to Evaluate a Leggings OEM Manufacturer

1. Fabric Knowledge & Testing Ability

A reliable leggings OEM should clearly explain:

- Stretch and recovery performance

- Opacity under movement

- Fabric shrinkage after wash

- Nylon vs polyester trade-offs

Ask if they provide test reports or wash testing.

If they can’t explain fabric behavior, expect problems later.

2. Pattern Engineering & Fit Ownership

Good OEMs don’t just follow size charts — they own their base patterns.

Critical fit areas:

- Front/back rise balance

- Crotch depth and curve

- Thigh and knee shaping

OEMs that copy patterns struggle to maintain fit across reorders.

3. Sampling Workflow & Communication

Strong OEMs offer:

- Clear sampling stages

- Written feedback after revisions

- Realistic timelines

Poor sampling communication almost always predicts bulk production issues.

4. Quality Control Systems

Leggings need tighter QC than casual apparel.

Ask about:

- Inline inspections

- Measurement tolerances

- Seam strength testing

- Final inspection before shipment

If QC only happens at the end, risks increase.

5. MOQ, Pricing & Long-Term Scalability

The right OEM should:

- Match your current MOQ

- Scale production without changing fit

- Maintain stable pricing logic

Choosing the cheapest OEM often leads to higher long-term costs.

Top Leggings OEM Manufacturers (With Links)

1. Fukigymwear – Performance Leggings OEM

Specializes in custom leggings OEM manufacturing with strong fabric testing, fit development, and QC control.

Best for: Performance-focused and private label brands.

2. Argus Apparel – USA-Based Leggings OEM

Provides pattern development, sampling, and domestic OEM production.

Best for: Brands prioritizing USA manufacturing.

3. Affix Apparel – Custom Activewear OEM

Low-MOQ OEM services with extensive customization options.

Best for: Startups and design-driven brands.

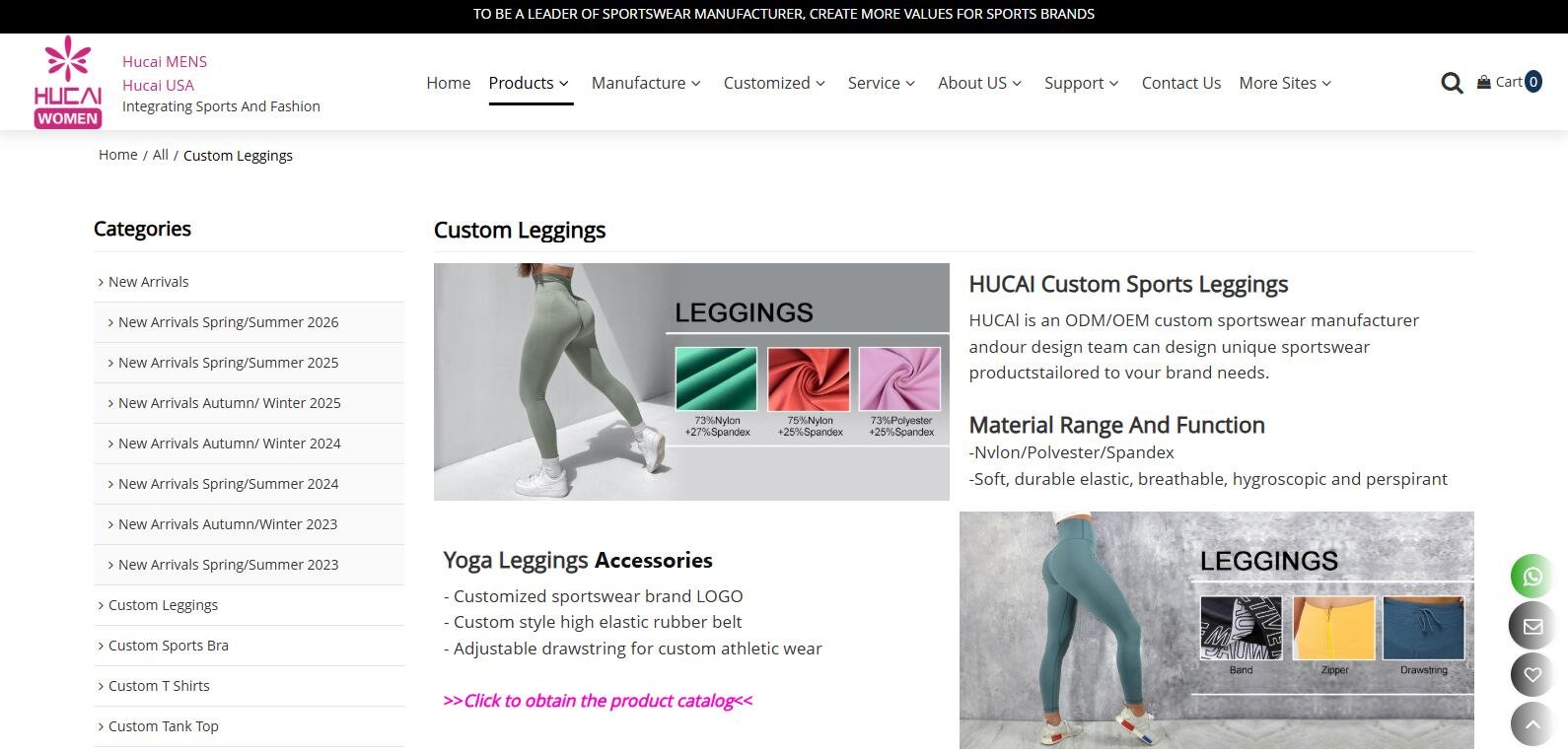

4. Hucai Sportswear – OEM Activewear Factory

One-stop OEM solution for leggings and gym wear.

Best for: Brands scaling bulk production with cost control.

5. Alanic – Global Sportswear OEM

👉 Alanic

Large-scale OEM manufacturer with international capacity.

Best for: Established brands scaling globally.

Comparison Table

| OEM Manufacturer | MOQ | Strength | Best For |

|---|---|---|---|

| Fukigymwear | Low–Mid | Fabric + Fit control | Performance brands |

| Argus Apparel | Mid | USA OEM | Domestic positioning |

| Affix Apparel | Low–Mid | Customization | Startups |

| Hucai Sportswear | Mid–High | Cost efficiency | Bulk orders |

| Alanic | High | Scale & capacity | Global brands |

How to Choose the Right OEM for Your Brand Stage

- Early-stage brand: prioritize communication and sampling support

- Performance brand: prioritize fabric testing and pattern engineering

- Premium brand: prioritize QC and consistency

- Scaling brand: prioritize capacity and repeatability

The right OEM grows with your brand — not against it.

FAQs

Q: What is a typical MOQ for leggings OEM manufacturing?

A: Usually 100–300 pcs per style depending on fabric and construction.

Q: How do I verify a factory’s leggings experience?

A: Ask for past leggings projects, fabric specs, and fit samples.

Q: Should I choose a local or overseas OEM?

A: It depends on speed, cost, and scale — each has trade-offs.

Work With Fukigymwear

If you’re looking for a reliable leggings OEM manufacturer that understands performance, fit, and consistency,

👉 Fukigymwear supports brands from development to bulk production.

We focus on long-term partnerships — not short-term orders.